How it's made

If you want to see how how our products are made, this is the place for you!

Transparency on every step

We believe that you should know what exactly goes into product you use. That is why we show every single step of making of our products and we disclose all our suppliers.

Learn how we transform soy wax and Jesmonite composite into art!

If you want to learn more you can watch more of the making process on our social media ♡

Candles

Total production time: 1 - 2 days (24 - 48 hours)

Melting – We put soy wax into the Wax Melter and warm it in around 70°C (158F). It can be more or less depending on soy wax brand – always read what the producer recommends.

Molds preparation – We warm the molds that need it to the right temperature. Warming the mold prevents frosting.

Pouring preparation – When the wax is fully melted we pour it into a clean, dry jug.

Color and fragrance – In this step we add any color or fragrance oil if necessary. We mix it for around 2 minutes so they are evenly distributed in the wax.

Wicks – We put the wicks into the molds.

Temperature check – We check the temperature of each mold before pouring the wax to ensure it’s perfect.

Pouring – We pour the wax into the molds. We advise to tap the molds gently to prevent occurring of the air bubbles.

Demolding – After 24 hours – demolding time! Our favorite step. Smaller candles may need less than 24 hours to fully cool down and bigger candles may need even more than 24 hours.

Common candle making problems and how we solve them:

Frosting

Uneven bottoms

Uneven color

Warming the mold to the right temperature before pouring wax – it is different for every mold, so you’ll need to experiment to find the perfect temperature for each mold. Even 5°C more or less makes a big difference. We check the temperature with a non-contact infrared thermometer.

Be careful not to overheat your molds – if the wax is poured into a mold that is too hot it will irreversibly damage the wax.

To achieve smooth bottoms you can either use a heat gun or a soap beveler.

Mix the wax with colorant longer or use a liquid colorant like us – it achieves an even color way faster and better than colorant chips.

Jesmonite home decor

Total production time: 2 - 3 days (48 - 72 hours)

Calculations – We calculate how much Jesmonite, terrazzo chips and pigment we need.

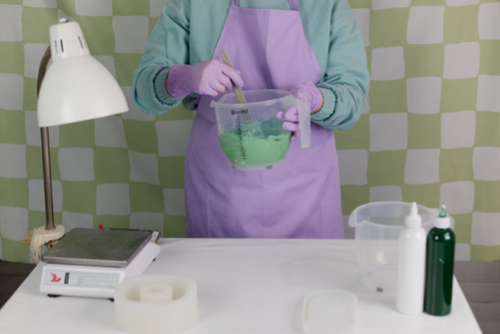

Mixing – We mix Jesmonite liquid, powder and pigment till it’s smooth – it takes around 1-2 minutes.

Terrazzo chips – We add and mix the terrazzo chips with a spatula.

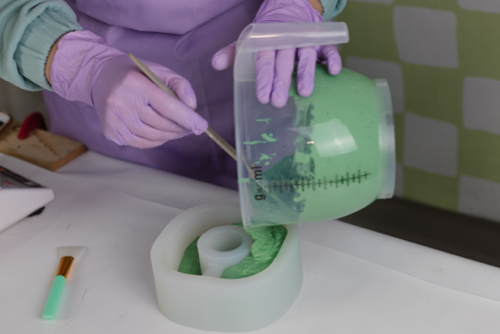

Molds – We put the mix into the molds and tap them gently till to prevent air bubbles as much as possible.

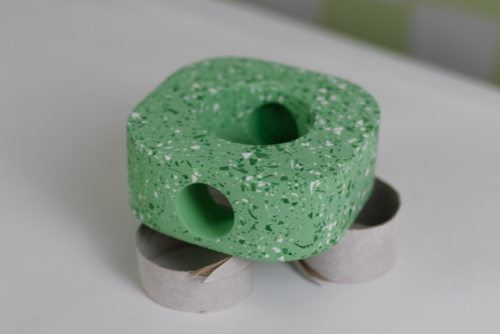

Curing – The mix will start to warm up and after around 1 hour it cools down and this is the moment to take products out of the mold. Jesmonite will gain its full strength after 24 hours – it needs all the moisture to evaporate to gain its strength.

Sanding – We sand all our products by hand and with a power sander with wet sanding paper in water. We use grids from 80 (to reveal terrazzo chips) to even 2000 (to smooth the surface).

Drying – Now we wait till everything is perfectly dry – it takes around 24-48 hours.

Sealing – We seal each product with Jesmonite sealer and add cork feet to prevent scratching other surfaces.

Thank you for being here ♡

- Alumi Studio